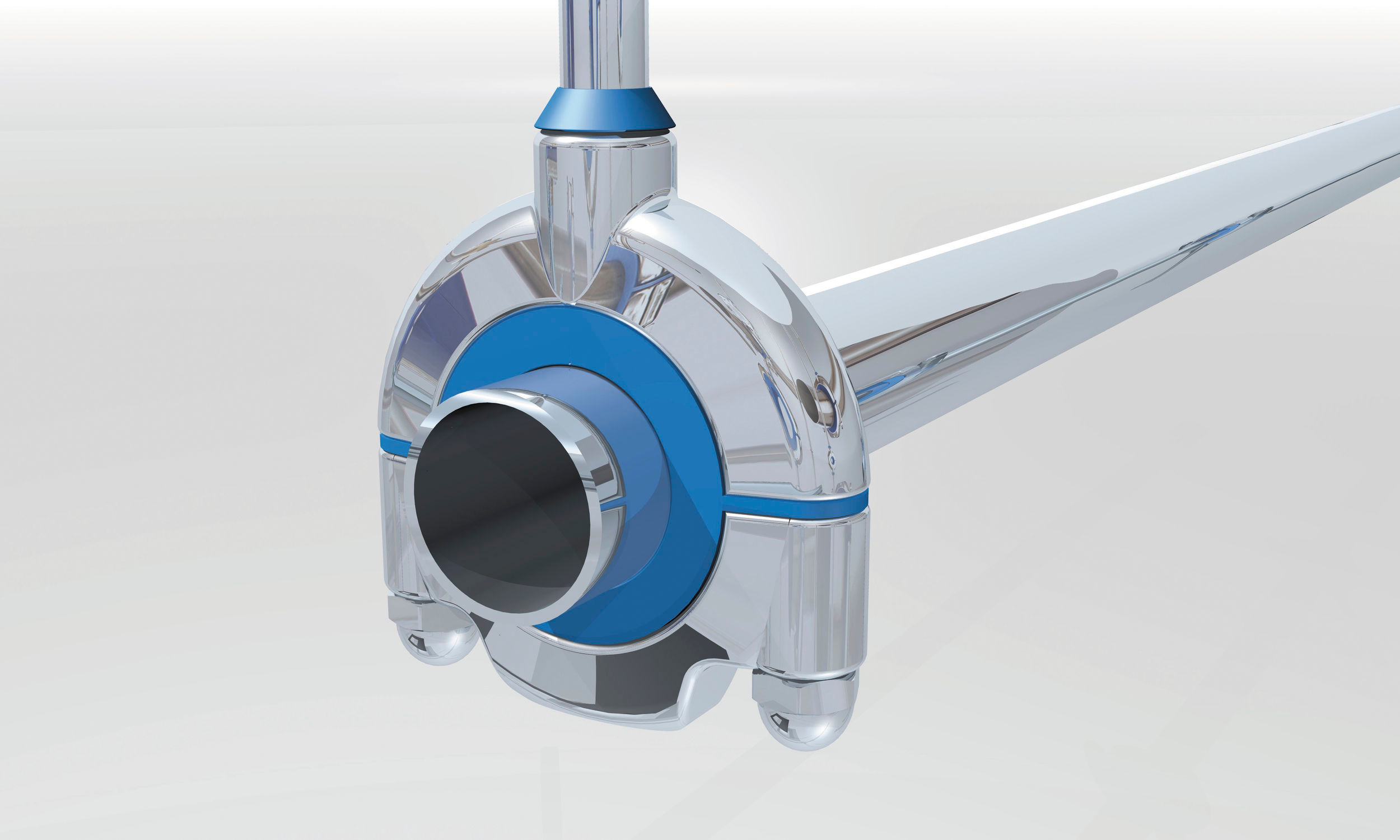

Sanitary Fittings & Sanitary Gaskets

ATC offer a wide range range of sanitary gaskets and o-rings. We also offer sanitary, fittings and tubing (also called hygienic fittings and tubing) to clients throughout Ireland. These sanitary fittings are user in the food, dairy, beverage, medical and pharmaceutical industries.

Sanitary gaskets are available in a range of materials including EPDM, Viton®, Buna-N, and Silicone and Fluoropolymer (PTFE). All compounds are FDA compliant. They allow for pipe and tubing connections to be made in a sanitary fashion that is designed to be cleaned in place (CIP) but is easily broken down for further cleaning, inspection and repair.

Sanitary fittings also are corrosion resistant and they limit entrapment areas where bacteria could form or propagate, thereby providing fittings that are hygienic and are ideal for use in controlled environments.

Sanitary Fittings provided by ATC include:

- Tri Clamp Ferrules

- Tri Clamp Clamps

- Tri Clamp Blanks

- Tri Clamp Gaskets

- Screen & Sock Gaskets with various mesh sizes

- Source gaskets

- Gauge gaskets

- Envelope gaskets with either EPDM or Viton filler

- Metal Detectable gaskets

The sanitary ferrules, clamps, blanks and gaskets listed above can be offered in a range of colours and materials including EPDM, PTFE, Silicone (Platinum & Peroxide Cured), Viton & Polysteel (PTFE mixed with 316 stainless steel).

- USP Class VI and FDA Certification available

- ADI/BSE/TSE free certification also available

- High Purity pipework and Fittings according to ASME BPE

- High Purity Platinum cured silicone hose

In addition to the above ATC can also offer the following unions:

- DIN

- DS

- IDF

- RJT

- SMS

Introducing Sanifluor

It’s well known that CIP (cleaning in place) utilizes chemicals that can attack the majority of elastomeric seals. SIP (sterilization in place) employs superheated steam which can even have an even greater detrimental effect. The traditional elastomeric sealing materials (Silicone Rubber, EPDM, Fluoroelastomer (Viton®) and Perfluoroelastomer (Kalrez) frequently fail prematurely when exposed to combinations of chemicals, high temperatures and steam/water. Teflon® falls short on its “sealability” characteristics. That’s because Teflon is a plastic and readily changes shape when compressed. When used as a sanitary gasket, it will typically work well on its first usage but after that it will likely cause some leakage. A failing/failed gasket or O-Ring will likely result in leakage, leaching and the risk of contamination. A common fix for leaking gaskets is continued tightening, but this is not a long-term solution.

Why use Sanifluor?

Sanifluor® 1000 elastomer was specifically formulated to overcome the vulnerabilities of Silicone Rubber, EPDM and Viton in these harsh environments. O-Rings, Gaskets and Seals produced from Sanifluor® 1000 have excellent chemical, heat and steam resistance. Their superior performance under harsh conditions makes them ideal for pharmaceutical, medical, biotechnology, food, beverage and cosmetic manufacturers who use steam or caustic chemicals in their sterilization processes. Sanifluor 1000 produces low TOC’s and metal extractables, and is both FDA and USP Class VI Compliant. It also complies with 3-A Sanitary Standard for multiple-use rubber materials. Sanifluor is recommended for service in processes that operate up to 450°F / 230°C.

Sanifluor® provides excellent performance in SIP (steam in place), CIP (clean in place) and WFI (water for injection) applications. Sanifluor® 1000 is available in all sanitary gasket sizes for Tri-Clover,® Tri-Clamp®, fittings, AS-568A O-Ring sizes and custom shapes. If you are looking for a solution to premature seal/gasket failure in CIP, SIP or similar aggressive environments, it is worth considering the use of Sanifluor®1000 gaskets and O-Rings.

For additional information, please feel free to contact us to see how Sanifluor can work for you.