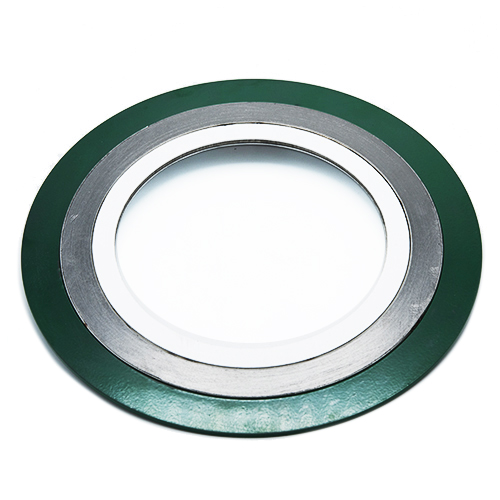

Spiral Wound Gaskets

Spiral wound gaskets are used in very high pressure applications or in very corrosive or high temperature environments such as pipelines in the chemical and petroleum industries. Spiral wound gaskets consist of alternating layers of compressible filler material and a metallic strip wound in a spiral (known as the winding).

The spiral can have inner or outer guide rings to assist in location. These guide rings can be of several metals but the standard is Carbon Steel zinc plated and passivated. The outer ring limits the gasket’s compression and acts to centre this type of gasket. Once the gasket is installed, the filler material is pushed between the plies, thus creating a seal between the flange mating surfaces. An inner ring gives additional compression and provides a heat and corrosion barrier protecting gasket windings and preventing flange erosion. Typically the inner ring material is the same as the metal winding.

Common filler materials include rubber, PTFE, graphite, non-asbestos jointing, etc. and will depend on the application. Graphite is a good general purpose choice. The winding material, filler material, guide ring material and the guide ring configuration can all be varied to fit the application.

A frequently specified spiral wound gasket configuration is:

- Spiral winding: stainless steel

- Filler: graphite

- Outer guide ring: carbon steel zinc plated

We also offer gaskets made from a wide range of other materials or tailor-made gaskets for particular client needs.

Contact us today to discuss your requirements.

Our team will work with you to determine the best solution to suit your needs. Fill in the form and our specialists will contact you as soon as possible.